Attesting to Al in Steel Construction

Fabricators discuss how implementing Al has improved productivity and share their experiences working with steel-specific Al.

Daniel Kamau, PENG, & Grayson Ingram, PHD

19 April, 2024

NOTE: This article was originally published in AISC's September Edition of Modern Steel Construction.

STEEL FABRICATORS can empathize with the hurdle put in front of Justin Airhart last year.

Airhart, the COO of AISC-member fabricator SSE in St. Bernard, La., lost one of his senior estimators in 2023. The experience level needed in that role and today's hiring challenges make filling the job and others like it an arduous and lengthy process. As limited manpower reduced his bid capacity and slowed revenue potential, Airhart jumped back into estimating, redirecting his focus from working on the business to working in the business.

Airhart filling the void was a temporary fix, though. Soon after, he turned to software automation technology to fill SSE's capacity gap and discovered how Al-powered innovations support the steel industry. SSE is among a growing number of fabrication companies to implement it in recent years.

As detailed in "Al Arrival" in the June 2024 issue of Modern Steel Construction, Al aims to train computers to think, learn, and solve problems like humans or, in some cases, better than humans. Modern algorithms still have a long way to go-most are known as "narrow" Al that specialize in a handful of functions. ChatGPT's ability to answer questions and write essays or Midjourney's ability to turn text into images using natural language processing falls into that category.

Those programs are trained on generalized data and aren't built for the risk-laden, safety-conscious, visual-data-heavy steel industry. Early applications of Al in steel largely revolve around computer vision — the "eyes" of the Al world that can identify, interpret, and manipulate images and videos. Some contractors and sub-contractors are using computer vision to collect data and report potential safety concerns, monitor machinery for predictive maintenance, examine products for defects, and manage inventory and logistical needs.

Limited-use cases have shown Al can increase efficiency, decrease financial bleeds, and fill gaps hollowed by labor shortages. Most Al programs weren't designed just for steel; they were co-opted from other industries. Al's true potential unfolds when Al developers and domain experts in steel businesses come together to create technologies that understand the steel business' needs and language.

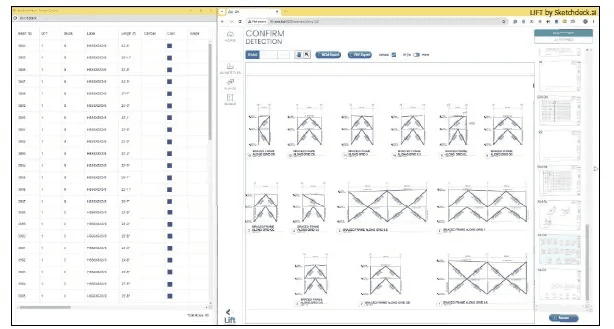

One of the first major Al and steel collaborations began in 2021 when a group of AISC-certified and member fabricators joined Al startup Sketchdeck.ai to build LIFT, an automated material take-off software that can read 2D engineering drawings. LIFT partnered with fabricators to ease the burden on estimation teams by identifying structural steel elements in bidding plans and exporting information into integrated software/BOMs.

As an early application of Al in steel, the journey of building and discovery was fraught with trial, error, and iteration— and has started yielding meaningful success. Early case studies have proven that teams using Al technologies like LIFT can evaluate and bid more work, increase speed without compromising quality, and alleviate the strain on human estimators, resulting in healthier revenues.

Increasing Bid Capacity Through Automation

Estimator teams can only complete bids so fast. The prohibitively time-consuming evaluation process presents significant barriers to growing revenue; companies inundated with requests are often limited by their actual bid capacity, with last-minute bids and double-stacked deadlines pinching the revenue bottleneck even tighter.

In fall 2023, Todd Weaver, CEO of the Metals Fabrication Company and an AISC Board of Directors member, encountered a shop slowdown right as two experienced estimators left the business. The increased workload and decreased capacity quickly overwhelmed MetalsFab's estimation team with many tedious tasks, and accuracy faced potential compromises as the team pushed faster bids with fewer members.

MetalsFab tapped Al to help alleviate the burden and noticed what Joe Sage, MetalsFab's IT manager, described as an "immediate impact" on productivity. Integrating the new technology into the team's workflow reduced take-off times by up to 50%, allowing estimators to spend more time on high-value tasks like reviewing bid details and scope documents. When the estimation bottleneck uncorked, turnaround times on bids contracted, bid capacity increased, and MetalsFab built a healthy backlog of awarded jobs in the following months.

Alleviating Talent Shortages

When Airhart's senior estimator left, he witnessed firsthand how hard the steel industry's labor shortages have hit estimation teams, whether they're ramping up growth or replacing lost talent. The time-consuming process required the stretched-thin fabricator to split precious hours between working on the shop floor and managing his business, limiting bid capacity and expansion potential. Even after onboarding, estimators often stagger under hefty workloads and tight deadlines that contribute to burnout and future talent losses.

"I've had problems finding competent, capable estimators who I didn't have to train," Airhart said. "I want to have the estimators | have, not worry about adding new talent, and still be able to grow."

Like MetalsFab, SSE integrated LIFT into their workflow to automate portions of the estimation process. Airhart's team immediately reported reduced estimation times up to 75%, with complex bid times dropping from six to eight hours to just 1. 5. The extra support eased the pressure on SSE's estimators, who could tackle their workload with renewed focus. Airhart even found more time to focus on exploring new client opportunities.

Bridging the Gap Between Speed and Quality

Troy Ernst, chief estimator at King Steel, Inc., is no stranger to the tightrope fabricators walk: increase speed and decrease accuracy, potentially landing more jobs that need more corrections, or decrease speed and increase accuracy, limiting bid capacity.

"You have human eyes looking at drawings, doing take-offs one piece at a time, and quantifying that. There are limits to human speed," Ernst said. "There's only so fast you can work to stay accurate."

Ernst's estimation team frequently faced manual take-offs that were time-consuming and prone to imprecision under tight deadlines. Adding more work to grow the business exacerbated their stress. Often, his estimators found themselves choosing between focusing on details, speed, or client engagement, leading to perceptions of disorganization.

Ernst implemented LIFT into King Steel's workflow to give his team a new tool to address the capacity-quality bid gap. The estimation team leveraged LIFT's ability to identify steel on plans and automate material take-offs to halve estimation times, freeing up room to focus on quality. The increased accuracy and reliability allowed King Steel to hone its competitive edge in a tight market, and soon, estimators were tackling new, exciting projects that hit the ideal balance of challenging and accomplishable.

Software that "Speaks Steel"

Estimators spend substantial chunks of time fiddling with software not designed for their needs.

"We automate a lot of things in our shop-fabrication processes, different things for the erectors - so we really wanted to integrate [automation] into the estimating department," said Mason Callagher, an estimator at MSE Inc. "The problem we found over 10 to 15 years was that it's hard to find estimators to do monotonous jobs like simple beams and columns data entry."

Those are tedious, time-intensive, and detail-heavy tasks that often lead to mental strain, eye strain, and, in some cases, low morale. Software that should, in theory, speed up the inefficient, error-prone process merely shifts it into another computer program and frustrates teams.

"We [looked at] other software that allows you to perform the take-off on the PDF, [but] you still have to perform your take-off manually," Callagher said. "In at least one of those cases, it really slowed things down. It didn't reduce the workload; it was just a different way of collecting the information."

MSE initially adopted LIFT to streamline take-offs from PDF drawings, but the estimation team soon found benefits beyond reducing take-off times by 95%. Having software fluent in steel-specific activities as part of the workflow allowed estimators to focus on less tedious tasks, interface with clients, and even enjoy the occasional caffeine break away from their workstations.

"We were just kind of doing it in an archaic way before," Callagher said. "[Now], we're finally doing things more efficiently with the right tools. It just makes it more fun, and you can't help but be a little happier."

Implementing Al Solutions

These four cases reflect just how much more fabricators, erectors, and other stakeholders in the industry can accomplish with less stress when they have the right tools in their arsenal. However, integrating Al isn't as simple as downloading traditional software. The differences boil down to three crucial facts:

Al learns on its own:

Al can learn from corrected mistakes and new data, improving its accuracy and capabilities with continued use. Unlike traditional software that requires human intervention to correct mistakes and add new features, Al specializes in real-time adjusting.

Expert-Al interaction should be collaborative:

Al tools are probabilistic, not deterministic, meaning they do amazing things but make surprising mistakes. Current Al is only as good as its training, and even advanced algorithms can hallucinate or fabricate outputs unsupported by data. (LIFT, for example, occasionally misidentifies building elements found in bid plans.)

For these reasons, it's helpful to think of Al as a digital collaborator capable of making errors but valuable for speeding up data-intensive tasks. It's common for companies to adopt a human-in-the-loop approach, where a human monitor partners with an Al algorithm to complete tasks and correct mistakes.

Al-empowered software can enhance ROI:

Al software integrates into existing processes and digital tools to enhance current functions or add new levels of scope and sophistication. Though businesses can benefit from free tools like ChatGPT, purpose built algorithms offer enhanced features and rewards so businesses can collaboratively automate more of their workflows with better results. Advanced Al requires more upfront time and resource investment than general Al, but its increased learning and output capacity delivers more impactful results to users' well-being and business' revenues.

Challenges and Future Outlook

As still-developing technologies, it's unsurprising that Al is unevenly implemented across industries. Steel has been slower to adopt Al than many traditionally creative fields for many reasons, among them:

A lack of Al technologies that know how to work specifically with steel and integrate easily into existing workflows.

The prevalence of on-the-job training in construction industries, which may spook fabricators, Gcs, and estimators away from more technical systems they perceive as requiring more advanced training or knowledge.

A lack of available upskilling programs to train existing workers to use more advanced systems.

Concerns about the impact of Al hallucinations on business' output and bottom lines.

The time and money expense required to acquire new systems— some fabricators prefer what they have over integrating what they don't.

Despite these challenges, businesses that implement steel-specific Al software can see substantial benefits in just weeks. MetalsFab's estimation team, for instance, enjoyed a 40% reduction in setup time per bid after adopting Al into its workflow.

MSE estimates that its team saved a whole work week per month in its first year of use. In both cases, supporting their estimation teams with custom-built Al resulted in more comprehensive bids, faster turnarounds, and increased flexibility.

Strategic partnerships and deployments have already revolutionized the steel industry, making companies faster, more efficient, and more profitable.

"| went from $8 million two years ago to $12 million to $30 million-and we're going to possibly hit $40 million this year," Airhart said.

Contrary to many fears, adopting Al isn't about outsourcing human labor. It's about capitalizing on human labor, building collaborative partnerships where humans delegate menial, data-driven labor to machine learning so they can focus on high-value tasks.

"Everybody's resistant to change; that's just human nature," Ernst said. "We've seen the value of innovation in this industry, and to stay ahead of the curve, you have to keep investing."

As Al grows, learns, and integrates deeper into life and industry, its transformative potential will ease labor shortages and inefficiencies, bridge gaps between speed and quality, and uncork workflow and financial bottlenecks. But it won't happen overnight or on its own. Businesses must prepare their teams by investing in technological education and selecting technologies that balance benefits, real-world uses, and growth potential. While there are challenges that need to be addressed, Al's integration has already shaped a more efficient, cost-effective future for the steel industry.

"We were just kind of scratching the surface before," Callagher said. "We realized that if you're not growing, you're dying."

More Blogs

How AI and Technology Are Transforming the Steel Industry in 2025

The steel industry is at a crossroads. With increasing competition, tighter timelines, and ever-growing demands for quality and efficiency, companies must evolve to keep pace. The bottom line is simple: those who don’t adopt new technologies will be replaced by those who do – or already have.

Read story

2024 NASCC Recap

The NASCC (North American Steel Construction Conference) in San Antonio was a thrilling event for all attendees, especially those interested in the intersection of artificial intelligence and the steel industry.

Read story

Arrival of AI in Structural Steel

The steel industry is increasingly turning to Al as one way to help improve efficiency and tackle problems.

Read story

Start Today

Reach Out and Let's Start Building Together

Have questions or ready to see LIFT in action? Our team is here to help. Contact us today to schedule a demo or discuss how LIFT can streamline your construction workflow and boost your project efficiency.